Is it possible to ‘future proof’ a superyacht?

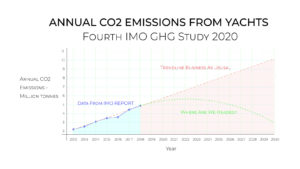

The reason for this question is that it doesn’t take much to realise that being able to switch your yacht from fossil fuel to green fuels in the future will have a positive impact on use, cost, and asset value.

Whilst these concerns and the transition away from fossil fuel seems to be far away, the impetus is growing and the reality is that when you take into account the design and build cycle along with the lifetime of a superyacht, you begin to understand why this may be an important consideration for anyone investing in a new build today.

Indeed, Lurssens recent announcement of a project using methanol and fuel cells may represent a paradigm shift for the industry. Though there are still questions about the availability of green methanol and storage and bunkering, this is probably the only superyacht in build that has the potential to adapt to a zero emissions future.

From discussions with other shipyards, it is clear that the environment is becoming an important consideration for some owners, and the pressure to act will only become more intense in the coming years.

The current narrative seems to be that ‘hybrid’ or ‘diesel electric’ (propulsion from electric motors) will allow you to simply remove the generators, replace them with a stack of fuel cells and then load up on green energy. On the surface these seems to make sense, however I think reality may be a little different.

When you look more deeply at the how, the challenge will not come from the replacement of the generators, it will come from the availability and choice of the green energy carrier that replaces the diesel fuel.

Currently hydrogen, methanol and ammonia seem to be the leading fuels in the drive to zero emissions shipping. LNG and biofuels also provide a useful pathway that helps reduce emissions but are unlikely to be the long-term solution.

The production of green ammonia or methanol, also known as ‘e’ fuels, require hydrogen produced via electrolysis using nuclear or renewable electricity and synthesis with air (e-ammonia) or CO2 (e-methanol). It is a very energy intensive process and methanol also depends on the supply of green CO2 e.g. biomass or direct air capture (DAC).

Due to the amount of energy required to produce these fuels and supply chain costs, these fuels are likely to be more expensive than today’s diesel. Technology and innovation in all its forms will still be necessary to reduce energy consumption.

Worth noting is that hydrogen, ammonia, and methanol, can be used in internal combustion engines (ICE). For example, the Ro-Ro/Pax carrier, Stena Germanica was successfully converted to run on methanol. This could provide another pathway for us; though I don’t know if these ‘gas’ or ‘dual fuel’ ICE’s are suited to superyachts? Maersk has also announced the building of a ship to run on methanol, whilst acknowledging that they are not entirely sure of fuel supply or infrastructure – I think it demonstrates a leadership that may help break the supply/demand impasse and drive change.

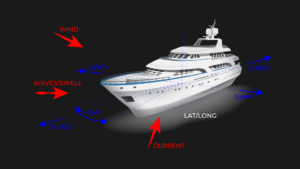

The major challenge with all these fuels for yachts, where space and aesthetics – a cryogenic hydrogen tank on the aft deck would not be ideal – are major factors, is that they are less energy dense than diesel, require more volume for the same amount of energy, along with special storage and enhanced safety due to the nature of the fuels e.g. flammable and toxic.

More information an be found in The International Maritime Dangerous Goods (IMDG) Code, International Code of Safety for Ship Using Gases or Other Low-flashpoint Fuels (IGF Code) and IMO MSC.1/Circ.1621 Interim Guidelines For The Safety Of Ships Using Methyl/Ethyl Alcohol As Fuel.

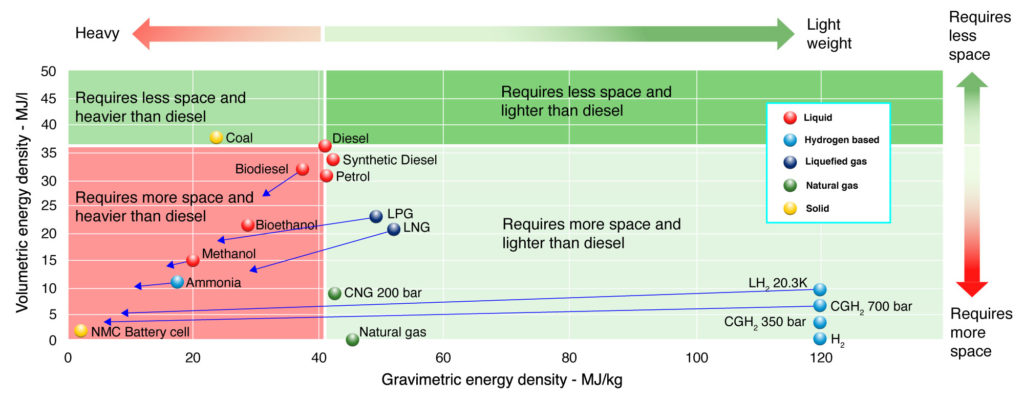

This excellent diagram of Volumetric and Gravimetric energy of various fuels from DNV-GL – Comparison of Alternative Marine Fuels, Report No: 2019-0567, Rev. 3, clearly highlights the energy differences.

Energy densities for different energy carriers (inspired by /49/ /72/ and /73/ of the report). The arrows represent the impact on density when taking into account the storage systems for the different types of fuel (indicative values only)

Hydrogen, due to the storage requirements, compressed or liquid, probably excludes its use directly as a marine fuel on superyachts though, as with shipping, it may be well suited to coastal cruising. Much more likely, as with the Lurssen project, is that methanol or ammonia is used as the energy carrier and converted back into hydrogen using reformers onboard if fuel cells are used.

The resultant hydrogen would then be used in Proton Exchange Membrane (PEMFC) or High Temperature Proton Exchange Membrane (HT-PEMFC) fuel cells. HT-PEMFC are less critical on the purity of the hydrogen and the heat can be used to improve the overall efficiency – though, to date, as an industry we have not been very energy efficient with the use of waste heat from engines or generators.

Although solutions for the storage, ventilation, safety and bunkering of methanol and ammonia will no doubt be found – it’s already carried onboard ships either as a fuel or cargo – how this is integrated into the hull of a superyacht may have some significant impacts on space, layout and, of course, range.

I think some caution is required before promoting the use of ‘hybrid’ or ‘diesel electric’ as ‘future proof’ solutions. We need to be able to demonstrate how this would work, the practicalities and impact on cost, safety, use, space and range to name just a few considerations. This will be crucial to the future growth of the industry as yacht owners and their advisors will need to weigh these factors in their decision-making process.

Finally, Lurssen and their visionary customer, may have found one pathway that helps answer the question. That is a real benefit to the future of the industry.