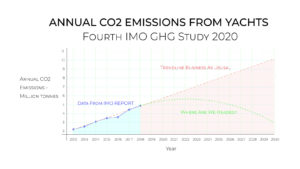

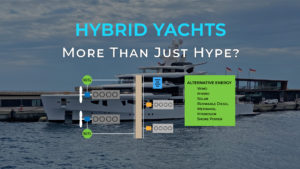

There has been much talk about reducing CO2 emissions from superyachts and apart from incremental changes that may be possible through technology such as hybrid propulsion, batteries, digitalisation and efficient hull design, the uncomfortable truth is it will not be sufficient to reach the goal of zero-carbon yachting.

The only way to achieve that goal is to move from fossil fuels to alternative fuels or energy carriers that are suited to the operational profile of the vessel. In the shipping industry batteries and Hydrogen are seen as viable solutions for coastal vessels where refuelling can be done regularly but, other fuels such as Methanol and Ammonia (very challenging on storage and safety) are seen as more practical for ocean going vessels.

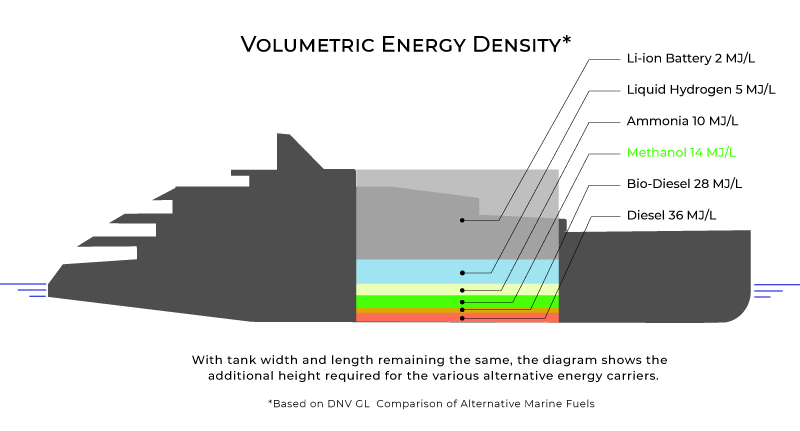

The main problem with Hydrogen and batteries is the volumetric energy density compared to fossil fuels – this can be seen in the diagram below.

This is certainly a consideration with superyachts where space is at a premium. Requiring more volume for fuel, ancillary equipment, and associated safety systems, will either compromise the interior, significantly reduce the range, or both.

Apart from bio-diesel such as 2nd generation Hydrotreated Vegetable Oils (HVO) the most promising fuel may be Methanol.

What is Methanol

Methanol is one of the four basic chemicals used to produce all other chemical products such as formaldehyde, acetic acid, and plastics.

Methanol is one of the four basic chemicals used to produce all other chemical products such as formaldehyde, acetic acid, and plastics.

It is a colourless water-soluble and biodegradable liquid at atmospheric conditions with a mild alcoholic odour. Energy density is approx. 14MJ/l compared to diesel which is 36MJ/l. It boils at 64.6 C and has a Flashpoint of 11 so requires additional precautions for use, storage and handling but, these are well understood.

It burns cleanly with no particulates, does not contain sulphur and the combustion of Methanol emits a very small amount of NOx. Engines using Methanol can be Tier III compliant without exhaust gas after treatment.

Methanol is mainly produced from natural gas or coal and, according to the International Renewable Energy Agency (IRENA), annual production is around 98Mt and accounts for about 10% of the CO2 emissions from the chemical and petrochemical industries.

Green Methanol

With all alternative fuels it is important to understand the GHG emissions along the whole value chain, including production, storage, transportation, and final use. Methanol does emit CO2 when combusted and in the reforming process for Hydrogen but, importantly, it can be carbon-neutral depending on the energy and feedstocks used in the production of the fuel.

Production methods include:

- Bio-Methanol from bio-mass such as agricultural waste, bio-gas, sewage, municipal solid waste and black liquor from the pulp and paper industry.

- E-Methanol from Green Hydrogen and, either CO2 from direct air capture (DAC), or carbon capture and storage (CCS)

Currently only about 0.2Mt of Green Methanol is produced. Studies suggest this is forecast to grow to 2Mt by the end of this decade. It is one of the easier fuels to scale as the technology is well understood and much of the infrastructure, such as storage and distribution, is already in place.

Availability

Like all alternative fuels this is a challenge, and much will depend on demand and the scaling up of production and bunkering infrastructure.

Shipping companies such as Stena and Maersk are already driving maritime demand, and the chemical industry will require Green Methanol to reduce their CO2 emissions. This increasing demand will provide the producers the confidence to invest in production and improving availability – it’s likely there will be more demand than supply in the early days.

In the meantime, Grey and Blue Methanol that use natural gas, carbon capture and renewable feedstocks, could be a suitable pathway until such time Green Methanol is more widely available.

According to the DNV Alternative Fuel Insight, Methanol is already available in 117 port terminals around the World, including Algeciras, Tarragona, Genoa, Livorno and Trieste. It can also easily transported by truck.

Maritime Fuel

A major benefit is Methanol, unlike Hydrogen and Ammonia, can be carried in structural tanks – the same as diesel. It does require additional barriers, double walled piping, ventilation, and inert gas, but there is wide experience in its transport and use. The IMO have produced guidelines for its use as a marine fuel under the IGF Code – Interim Guidelines For The Safety Of Ships Using Methyl/Ethyl Alcohol As Fuel (MSC.1/Circ.1621).

It can also be used in diesel engines and reformed to produce Hydrogen for Fuel Cells.

Diesel Engines

Diesel engines are a mature technology with some engines around 45% energy efficiency at optimum power. Overall efficiency can be further improved by using hybrid systems, waste heat recovery and power management to optimise engine performance and electricity generation. In addition, they are well suited to running on alternative liquid and gaseous fuels.

In a recent White Paper titled “The Future of Internal Combustion Engines” Rolls Royce maintain combustion engines will continue to play an important role but, with a steady transition away from fossil fuels to sustainable fuels. And, as well as new engines optimised to run such fuels, they also see the need to offer conversion kits for existing engines.

As an example the Stena Germanica, operating in an Emissions Control Area (ECA) between Germany and Sweden, was successfully converted in 2015 to burn Methanol in its engines.

AP Molller Maersk believe in the fuel for shipping and have signed a contract for 8 x 18,000 TEU container ships to be delivered in 2024 with engines running Green Methanol.

ScandiNAOS has produced a diesel engine with power outputs from 150 – 450kW that runs on Methanol for propulsion and genset applications. Approved by Lloyds and DNV.

Image: Courtesy of ScandiaNAOS

There is no doubt that in the coming years we will see most engine manufactures launch new engines to run on alternative fuels such as Methanol, as well as upgrade kits for their existing engines.

Fuel Cells

Most Fuel Cells require Hydrogen, and Methanol is a great source of Hydrogen.

Unfortunately, whether Hydrogen is stored as a liquid or a compressed gas, it has low volumetric energy density. You need about 7 – 10 times more volume than for the equivalent amount of diesel, whereas Methanol requires about 2.5 more volume.

Methanol can be reformed into Hydrogen onboard for use in the Fuel Cell. And, interestingly, there are reformers that use a blend of di-ionised water to achieve 30% – 40% more Hydrogen, compared to using pure Methanol.

This and the other characteristics of Methanol, make it an ideal fuel for Fuel Cells.

Superyachts

Lurssen have announced they are building a 100m+ yacht that will use reformed Methanol in a Hydrogen PEM-FC as part of the energy mix.

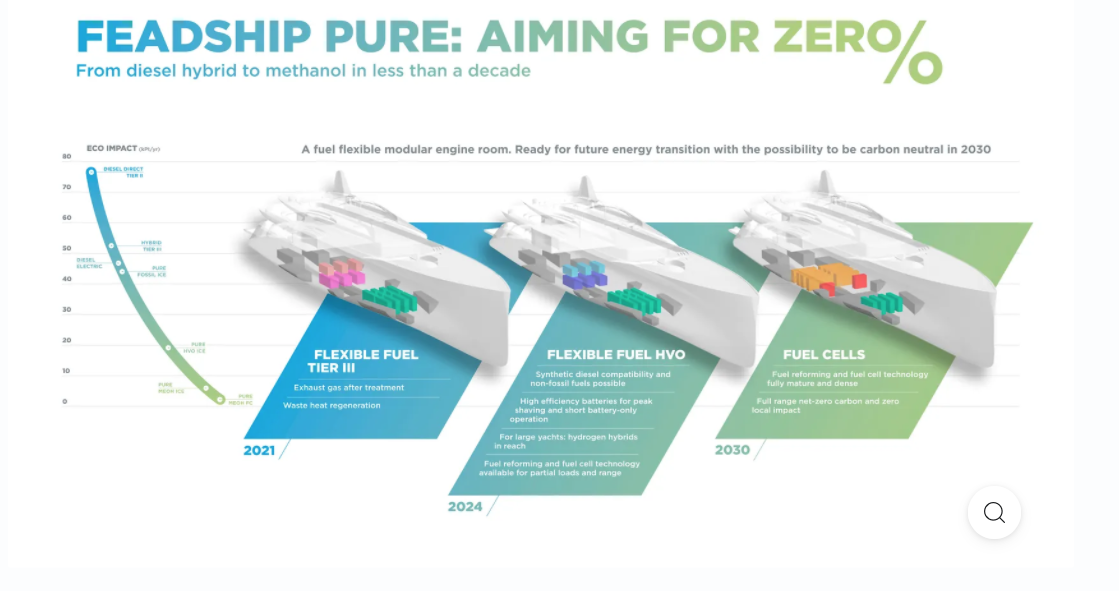

Feadship, with the ‘Pure’ concept, have engineered different solutions that will allow for a phased transition from Diesel – HVO – Methanol by including this pathway in the design and build. Partial or full conversion to Fuel Cells may also be a possibility.

Copyright “Feadship”

Though the above are large yachts, the Fastwater Project has recently shown how it can be used in a smaller vessel. They successfully converted a Swedish Pilot boat to run on Methanol.

Future Proof

The idea that electrification of superyachts via hybrid or diesel electric will ‘Future Proof’ a yacht misses a critical component, the fuel. Claims of this type need to be treated with caution.

It’s one thing to swap out a diesel engine for a Fuel Cell, but it’s a totally different matter to convert a yacht for a fuel that is higher risk and less energy dense. Apart from the high cost, it is unlikely to be practical without significantly compromising space and/or range.

Building a yacht ‘Methanol Ready’ by including the extra tank capacity, cofferdams, ventilation, piping and, later inert gas system, would be one way to ‘Future Proof’ a yacht. And, like ‘Pure’ It would allow the yacht to initially run on MGO or HVO and, in the future, covert the engines to run on Methanol and allow hybrid solution that includes Fuel Cells in the mix.

Conclusion

The evidence suggests that Methanol is a serious alternative to diesel fuel that would significantly reduce a yachts GHG emissions and improve overall air quality.

There are still some challenges to overcome such as the availability of Green Methanol, though Grey and Blue Methanol could help with the transition.

A limiting factor at present is the availability of engines and/or conversion kits. The indications are that we will see more these in the next few years, and with the power required by superyachts. And, although PEM-FC are relatively mature, combining reformers in a maritime setting in MW scale, is less so, and may restrict earlier adoption. However, a hybrid solution using Methanol engines and PEM-FC could certainly be a viable solution in the near term.

Methanol clearly has advantages over many of the alternative fuels. Given the available build slots and projected launch dates, a forward-thinking owner might be well advised to consider the use of Methanol in their next superyacht to not only protect the environment but also protect the future value of their investment.